-

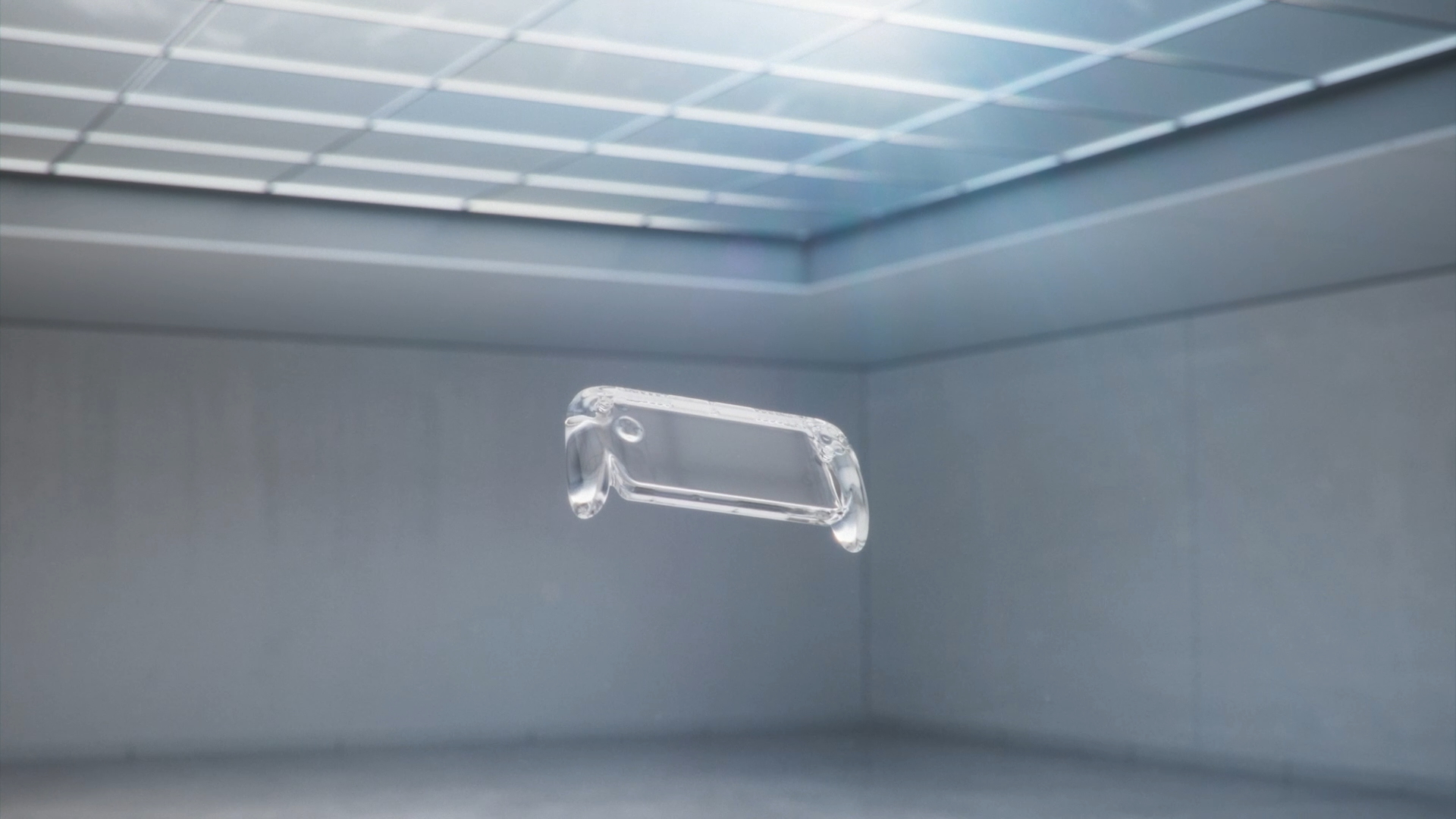

XBOX

“ROG XBOX ALLY”

Microsoft and Asus have partnered to launch the first Xbox gaming handheld device, the ROG Xbox Ally. The announcement was made during the Xbox Games Showcase in June 2025, with a reveal trailer created by Droga5 and produced by LOBO.

-

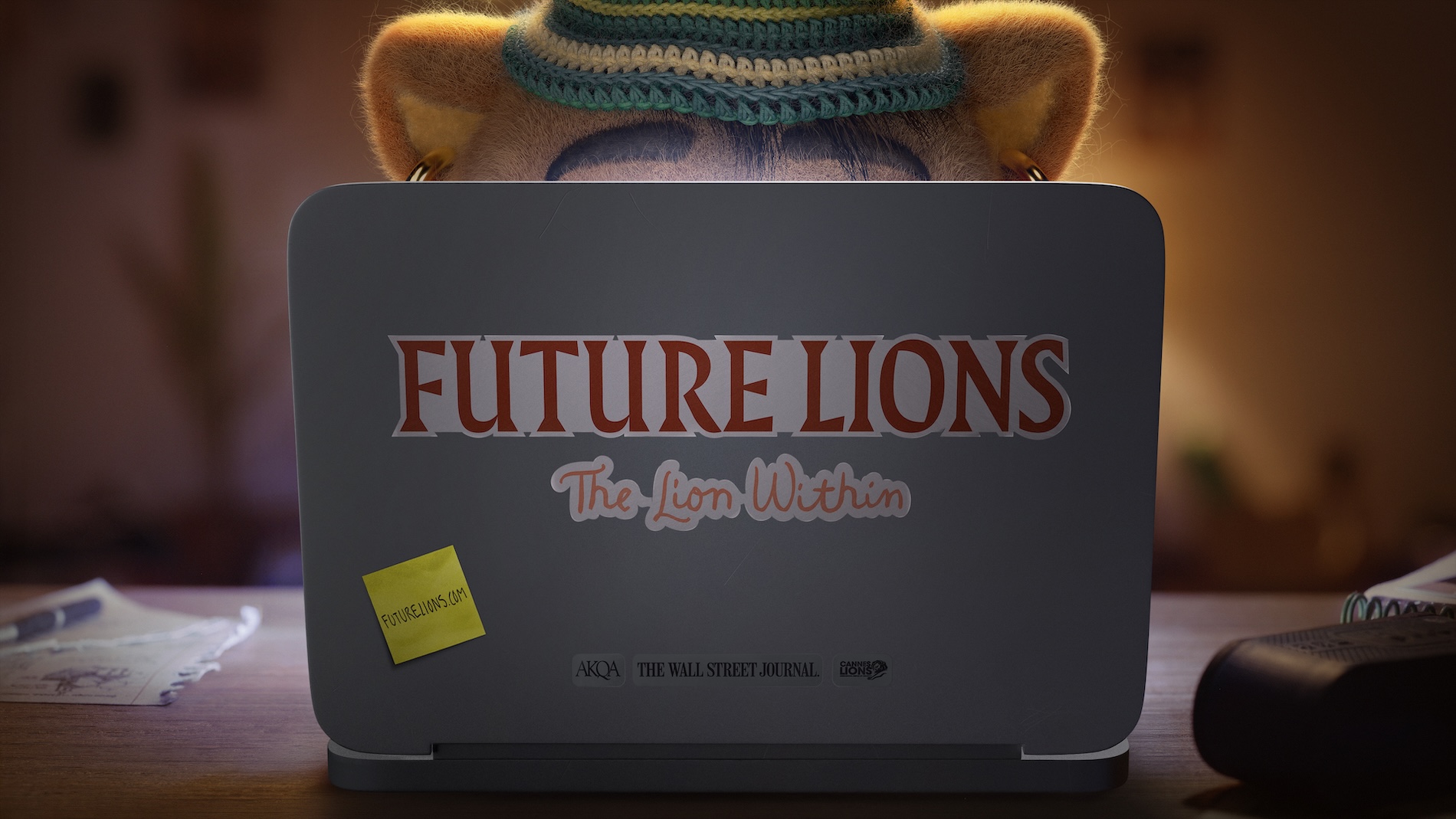

The Lion Within

FutureLions Cannes Festival

Future Lions, the global competition founded by AKQA in partnership with the Cannes Lions International Festival of Creativity, marked its 20th anniversary with a bold animated campaign that captures the drive, doubt, and determination of young creative innovators.

-

Vanish

"The invisible Stain"

We believe animation has a unique power—it can make complex topics more approachable while still packing an emotional punch.

W

e

a

r

e

L

o

b

o

,

a

c

r

e

a

t

i

v

e

s

t

u

d

i

o

d

e

d

i

c

a

t

e

d

t

o

m

o

v

i

n

g

i

m

a

g

e

s

.

O

u

r

e

x

p

e

r

t

i

s

e

c

o

v

e

r

s

a

b

r

o

a

d

r

a

n

g

e

o

f

m

e

d

i

a

a

n

d

t

e

c

h

n

i

q

u

e

s

,

l

i

k

e

2

D

a

n

i

m

a

t

i

o

n

,

s

t

o

p

m

o

t

i

o

n

,

3

D

,

V

F

X

a

n

d

l

i

v

e

a

c

t

i

o

n

.

L

e

t

u

s

s

h

o

w

y

o

u

a

b

i

t

o

f

o

u

r

w

o

r

k

L

e

t

u

s

s

h

o

w

y

o

u

a

b

i

t

o

f

o

u

r

w

o

r

k

W

o

u

l

d

y

o

u

l

i

k

e

t

o

s

e

e

m

o

r

e

o

f

o

u

r

w

o

r

k

?

W

o

u

l

d

y

o

u

l

i

k

e

t

o

s

e

e

m

o

r

e

o

f

o

u

r

w

o

r

k

?

F

e

e

l

f

r

e

e

t

o

c

o

n

t

a

c

t

u

s

F

e

e

l

f

r

e

e

t

o

c

o

n

t

a

c

t

u

s